New features

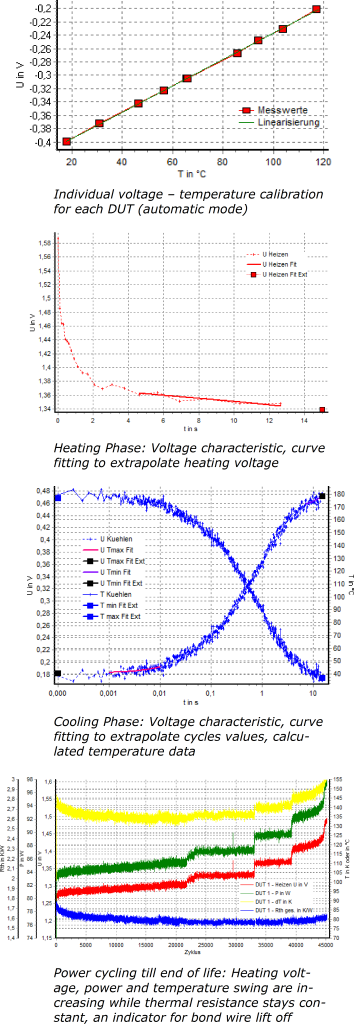

- Time dependent temperature voltage calibration for the latest SiC power semiconductor generations

- Individual current source for each DUT offers highest flexibility

- High measurement current up to 3A

Active Power Cycling Test

In power electronics the demand on highly reliable and cost effective systems is the present situation. To fulfill these requirements, precise lifetime models have to be developed. An essential element is a good data basis generated by tests. The semiconductor’s electrical and thermal joining is best examined by active power cycling tests. The device under test (DUT) is heated and cooled by its own power loss characteristic. The accelerated aging is mainly driven by diffusion processes and thermo-mechanical stress. The result is a degraded electrical and/ or thermal contact. Both can easily be monitored. If the power cycling is continued till end of life, the physics of failure method will help to design an appropriate lifetime model. At least wear-out failures are in the focus. Competitive testing of different technologies or assembly parameters ensures comparability to other tests. Parallel testing of identical devices represents the statistical distribution.

The PCT3 power cycling test system offers a wide range of applications. High flexibility associated with automatic start-up processes contribute to that.

Applications

- Research

- Development

- Qualitification

Heating and Cooling

- Heating current up to 400A, optional up to 800A

- Heating voltage up to 30V, optional 35V

- Easy to use and low cost load switches

- Tempering unit

cooling power 20kW, heating power 9kW - Coolant temperature up to 150°C

- Open or closed hydraulic secondary circuit system

maximum absolute pressure 10bar - Coolant pressure and flow rate sensors

- Automatic refilling of coolant

- Self adjusting temperature control

- Accepts water/ glycol mixture

- Test chamber with drawer for cold plate and DUTs

Measurement Features

- Various DUTs possible:

Diode, IGBT, MOSFET, JFET, BJT - Different test strategies from

application near (fixed heating current) to

scientific (fixed temperature swing) - Cycling time 0.1 to 3600s

- Indirect junction temperature measurement principle for DUTs, input voltage -10 to +10V

- Individual gate voltage/ base current control

for fine tuning of the heating power of DUTs - Gate voltage -20 to +20V

- Base current -100 to +100mA

- Measurement current -100 to +100mA

- Individual Pt100 temperature sensors for DUTs

- Global Pt100 temperature measurement

- Automatic temperature/ voltage calibration for indirect temperature measurement

- Time dependent temperature voltage calibration

- Automatic temperature swing adjustment

- Control of the individual temperature swing

for each DUT by gate voltage/ base current - Synchronous data logging of up to 20 DUTs

- Logging of heating phase

(voltage over time) cycle by cycle - Logging of cooling phase

(temperature over time) cycle by cycle - User interface to set timing intervals

for the fine tuning of the indirect temperature measurement - Calculation of heating power, temperature swing and thermal resistance

- Supervision of DUTs parameters like heating power, heating voltage, coolant temperature, global and individual external temperature sensors, minimum and maximum temperature, temperature swing, gate leakage current, base current and measurement current

Post Calculations

- Post calculation of thermal impedance cycle

by cycle (optional) - Display of Foster and Cauer equivalent network values over cycles (optional)

- Identification of thermal coupling among different DUTs in one setup,

e.g. devices in a B6 bridge - Different post data processing possibilities to enhance data quality

- Tools to proof data quality in terms of measurement interference

- Data reduction functions

- Data export functions

Miscellaneous

- Modular design of the data acquisition

- Integrated computer with uninterrupted

power supply for robust data storage and

visualization - Single file project data

- Emergency shut down (hand-held emergency stop, water alarm, smoke detector)

- Quick connectors with double shut-off for all hydraulics

- Quick connectors for heating power

- Cold plate ready to use (optional)

- Complete power cycling test system with minimal installation overhead